Our Products

We Manufactured

Explore Our Products

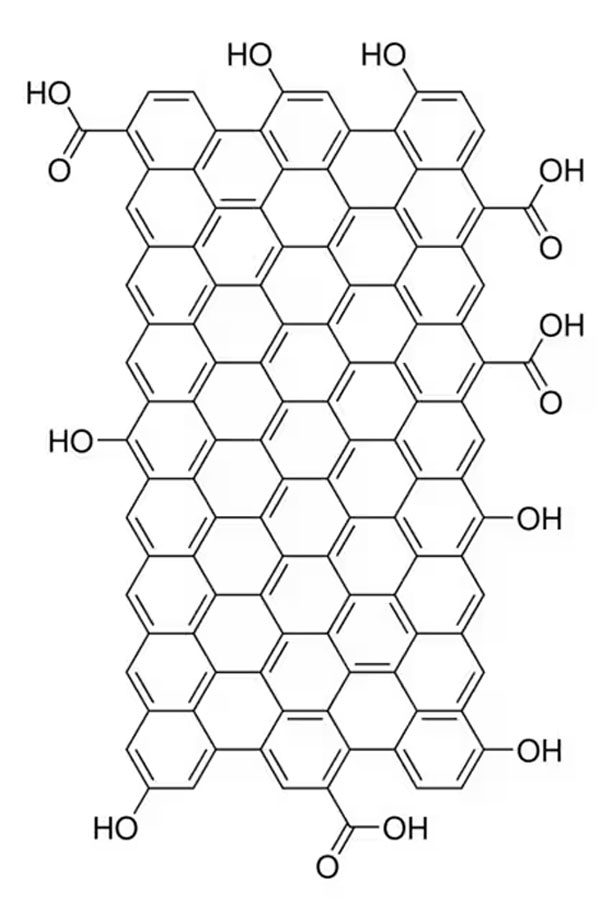

A comprehensive product and technology portfolio that focuses on four fields of carbon Capable of being produced to a range of bespoke customer specifications, we have the capacity to manufacture to custom dimensions and requirements.

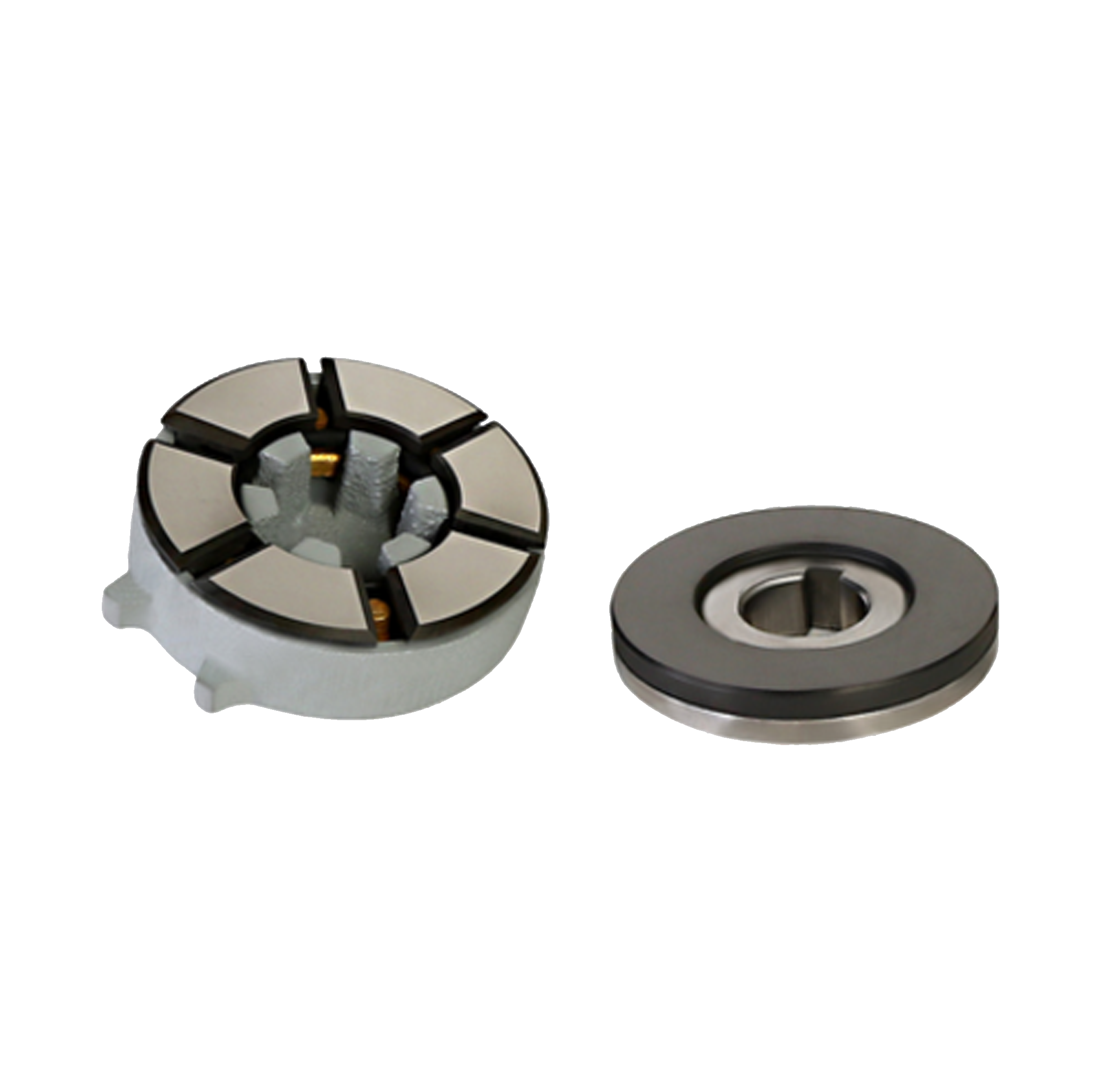

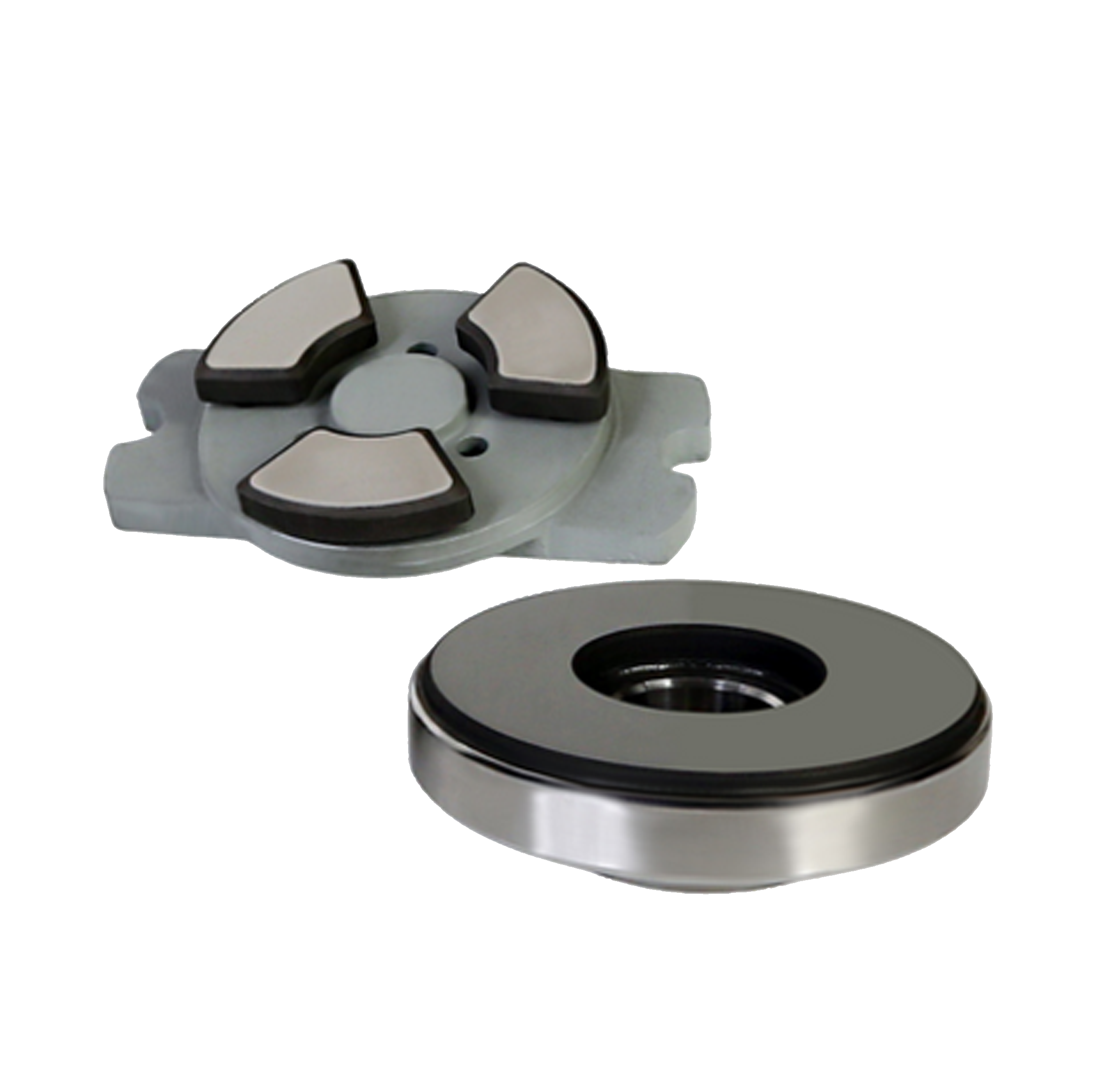

Designed to withstand varying thrust loads, our Carbon Thrust Bearings ranging from 3 inches to 12 inches, cater to a power range of 0.5HP to 300HP, ensuring optimal performance in submersible motors and vertical or horizontal pumps.

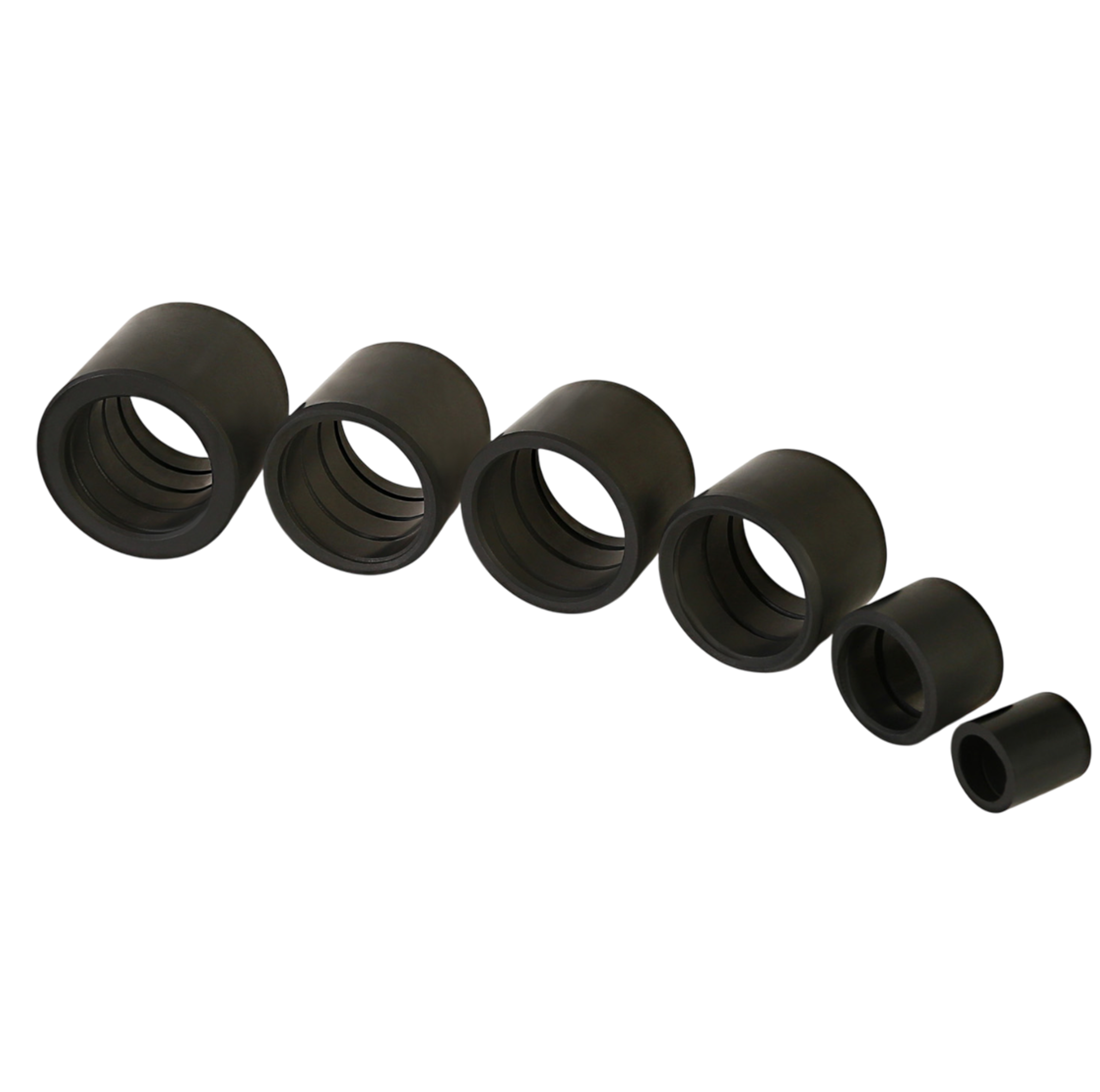

Crafted with precision, our Metal and Resin impregnated Radial Bushes offer friction-free performance ideal for submersible motor requirements, enhancing overall efficiency by reducing starting currents.

Renowned for their reliability, our Graphite Sealing Rings find critical application in defence aircraft engines, offering superior performance in static and dynamic aerospace sealing ring applications across various sectors.

A throat bushing in a pump isolates the mechanical seal environment from the overall flow within the pump. By changing the clearance at the throat bushing, pressure in the seal chamber and seal flush flow rate can be manipulated to provide a better sealing environment.

Used in the fuel injector assemblies of diesel and petro engines, the carbon piston assembly ensures precise and smooth operation of the injection mechanism even under demanding engine conditions.

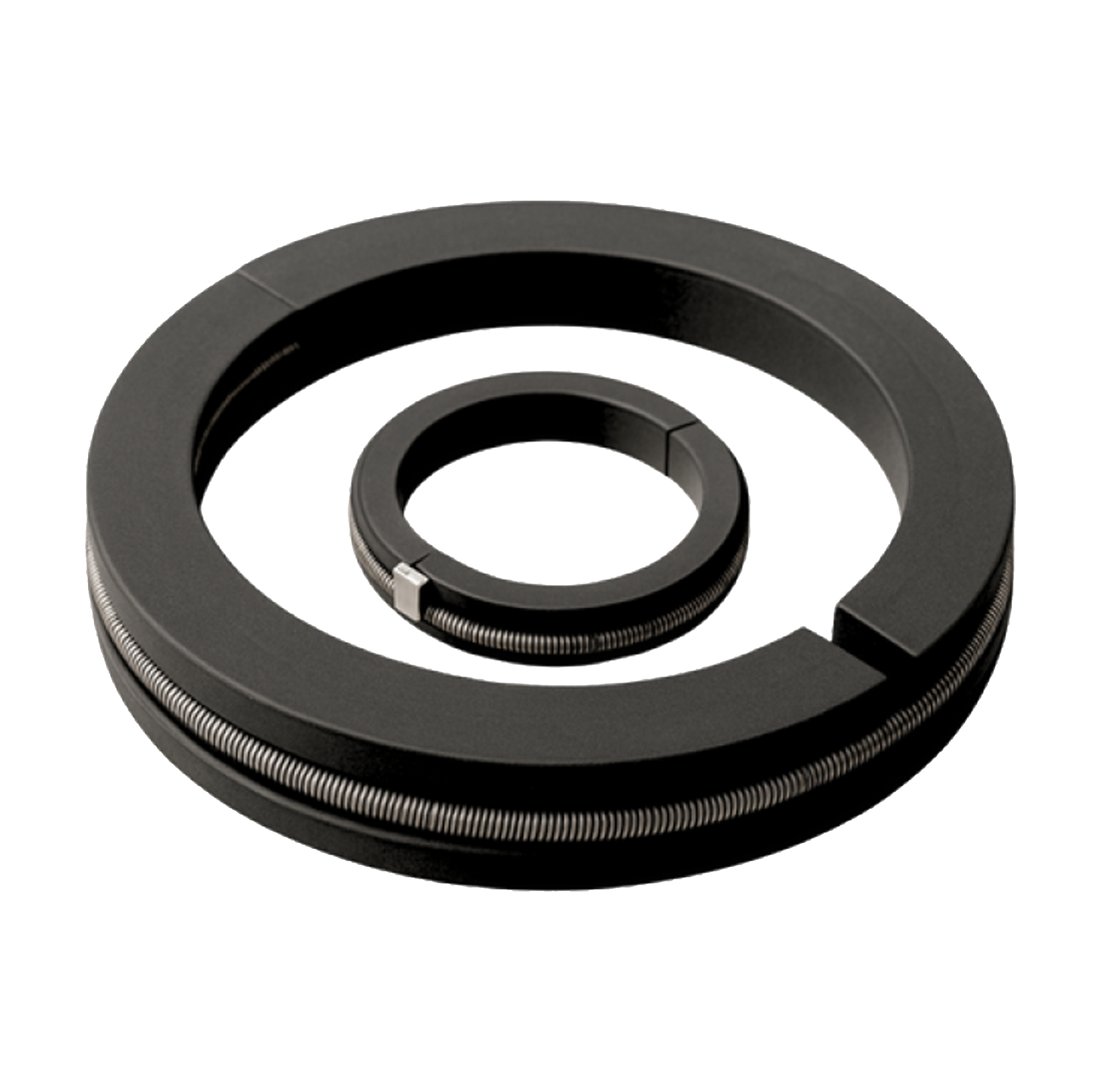

Designed for high-performance sealing in pumps, compressors, and agitators, our carbon/graphite mechanical seals offer exceptional chemical resistance, low friction, and excellent thermal conductivity. Suitable for handling corrosive fluids and high-temperature operations, they ensure long-lasting reliability and minimal wear in dynamic sealing applications.

Engineered for rotating equipment that transfers steam, water, oil, or other media, our rotary joints made from carbon/graphite materials provide superior heat resistance, dimensional stability, and low friction. Ideal for textile, paper, plastic, and chemical industries, these joints ensure smooth rotary motion and leak-free operation under extreme temperatures and pressures.

In paper and pulp mills, carbon stoker bushes are crucial components in boiler feed systems and fuel-feeding mechanisms. Designed to perform under high temperatures and abrasive conditions, these bushes offer excellent thermal shock resistance and self-lubrication. Their robust design ensures trouble-free operation in continuous processes like biomass or coal-fired boiler systems.

Our carbon/graphite gland rings are ideal for sealing shafts in pumps, valves, turbines and mixers, especially in high-temperature and corrosive environments. They provide excellent wear resistance, thermal stability, and a low coefficient of friction, reducing leakage and maintenance downtime in both static and dynamic sealing conditions.

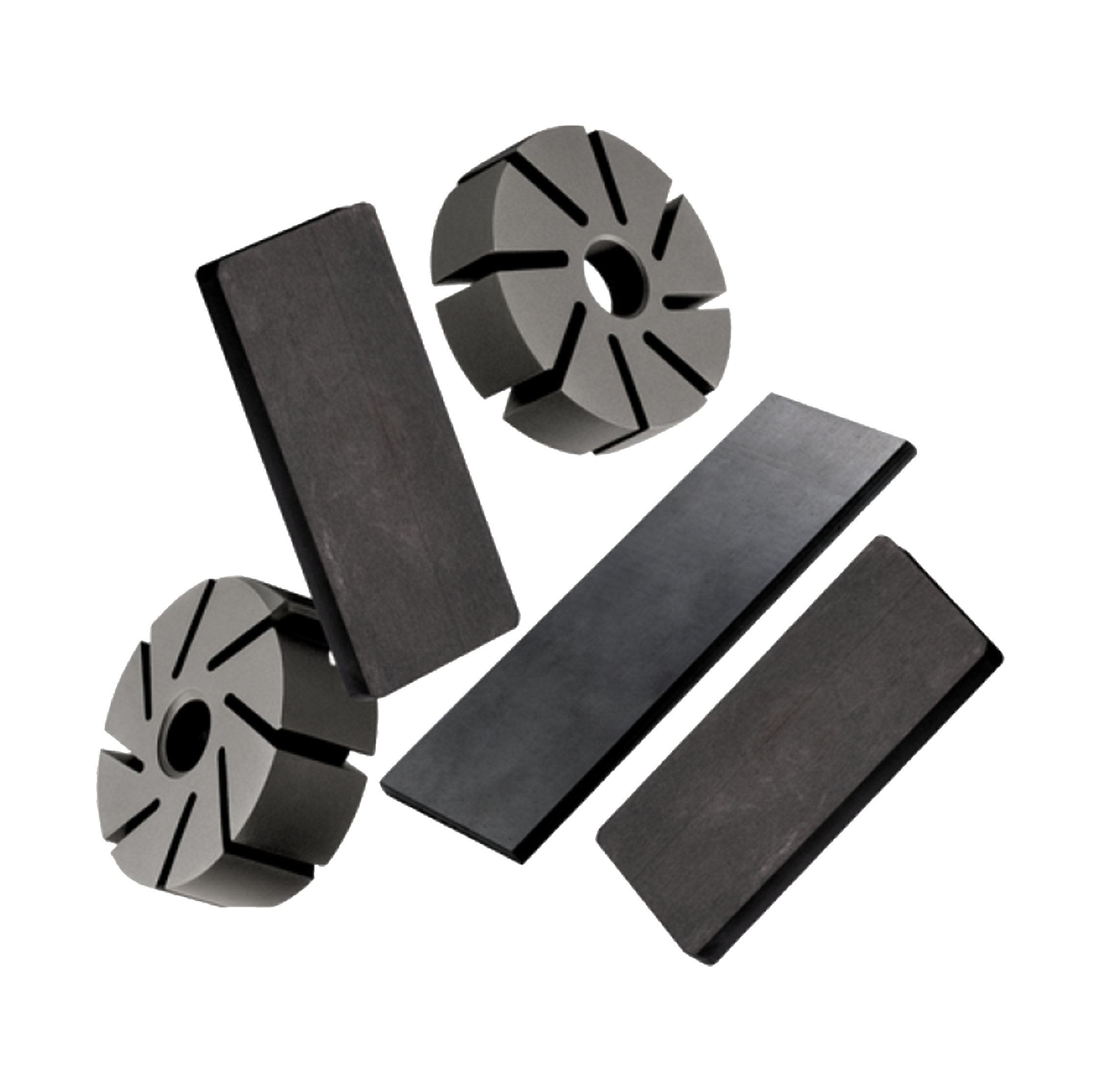

Perfect for dry and wet-running vacuum pumps, compressors, and air motors, our carbon vanes and rotors exhibit excellent self-lubricating properties and wear resistance. They deliver high efficiency, low noise, and extended service life even under demanding operating conditions, ensuring consistent performance in rotary vane systems.

Carbon/Graphite Bearings